our services

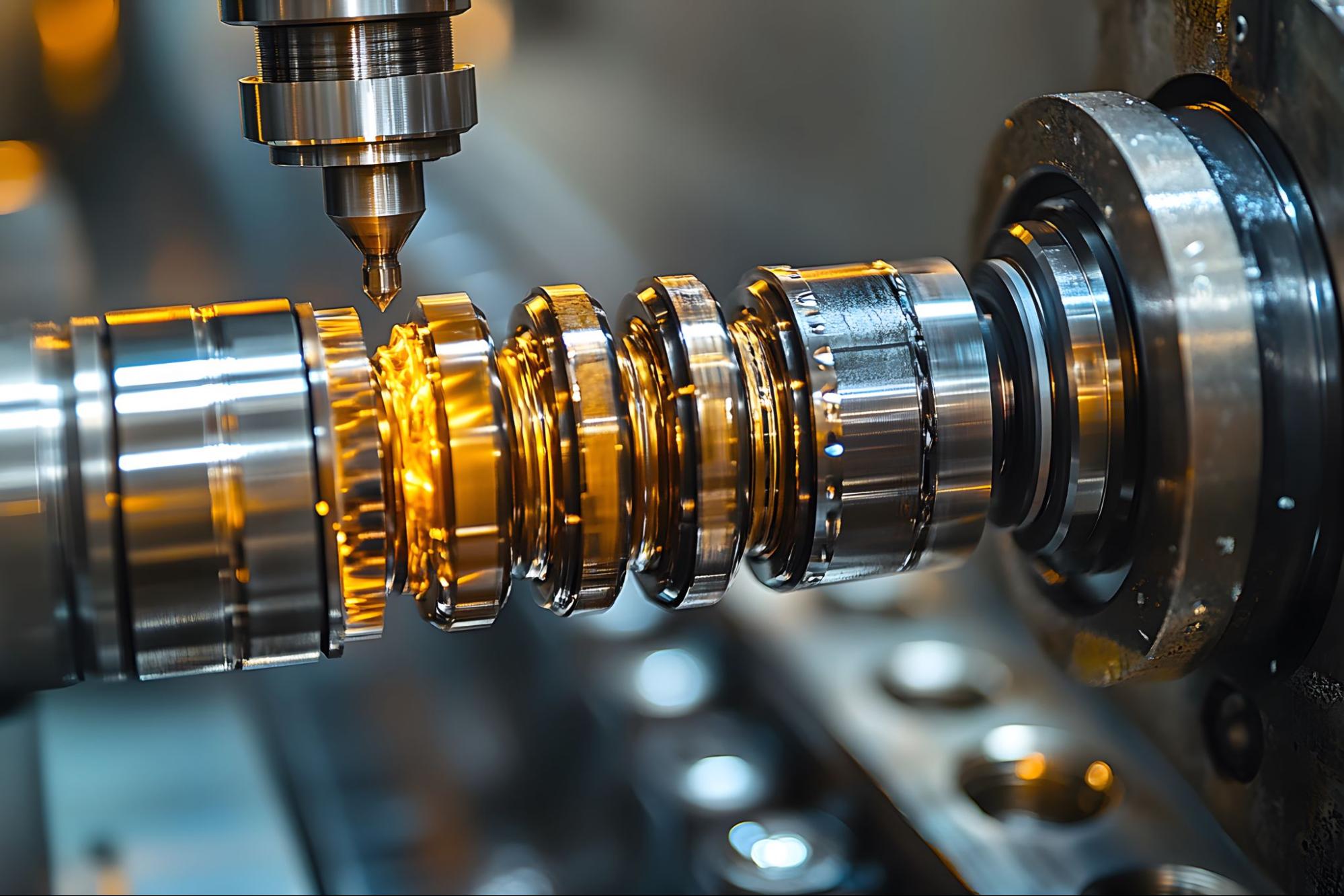

CNC Mill Machining

We use the latest technology for increased consistency and precision including CNC machining. CNC machining performs curves as easy as straight lines and makes complex 3-D structures relatively easy to produce.

CNC automation reduces the frequency of errors and provides our CNC operators with time to perform additional tasks. CNC automation also allows for more flexibility in how parts are regulated in the manufacturing process, and time required changing components can be adjusted.

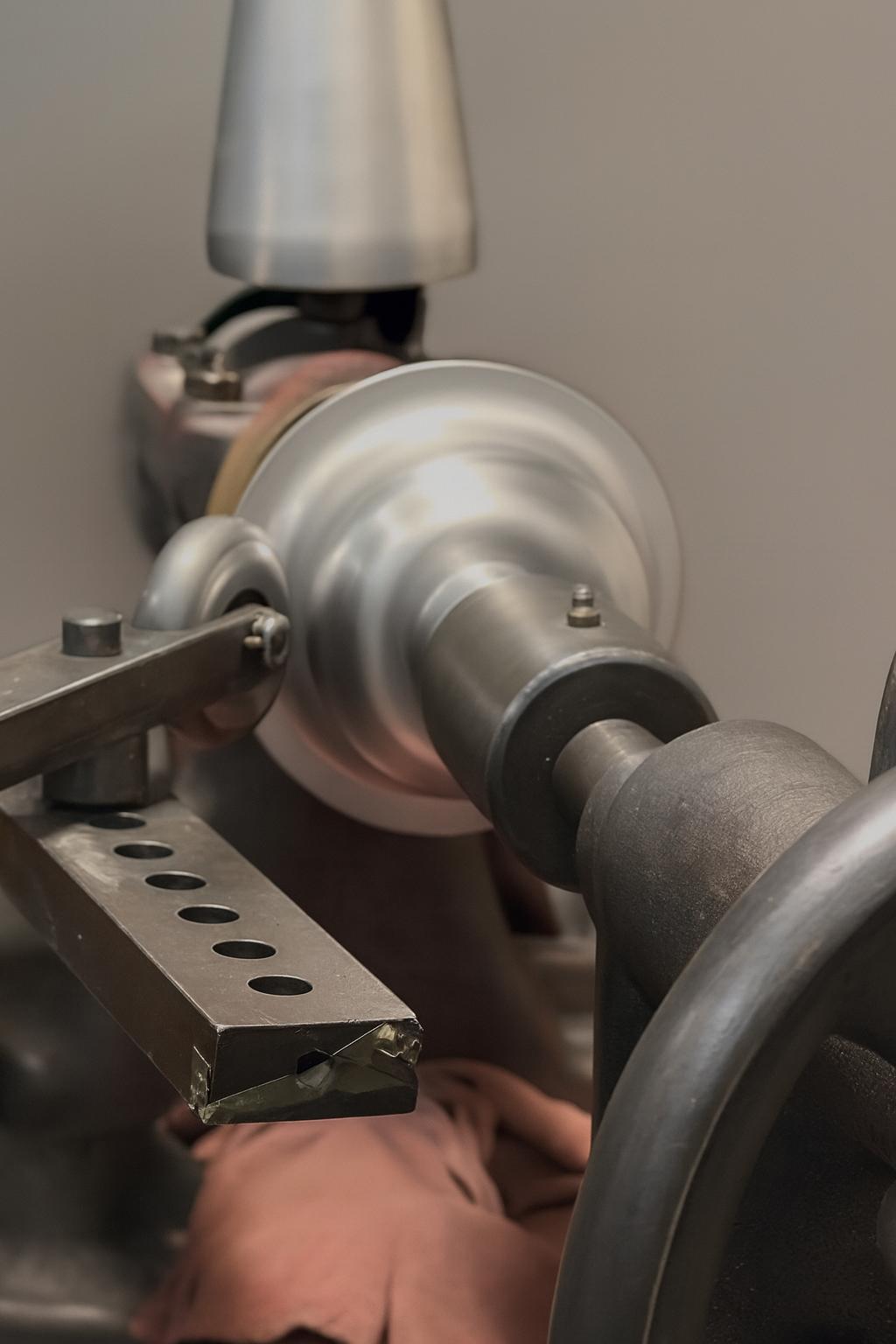

CNC Lathe Turning

CNC lathe, or Computer Numerical Control lathe, is a machine tool that uses a computer program to rotate a workpiece while a cutting tool shapes it to create round, cylindrical parts. We cater to automotive, aerospace, medical, and modern machines.

Welding

RMI Welding is NADCAP accredited in accordance with SAE Aerospace Standard AS7003. Our welding staff consists of highly skilled individuals with several years of experience in aerospace and commercial welding. We are constantly growing and expanding to meet the demand of our customers.

CNC Water Jet Cutting

Using a mixture of water at high velocity and pressure and various abrasive substances, Water Jet Cutting is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods. Water Jet can be used for simply cutting, shaping, carving, and reaming and does not cause heat damage to material surface or edges.

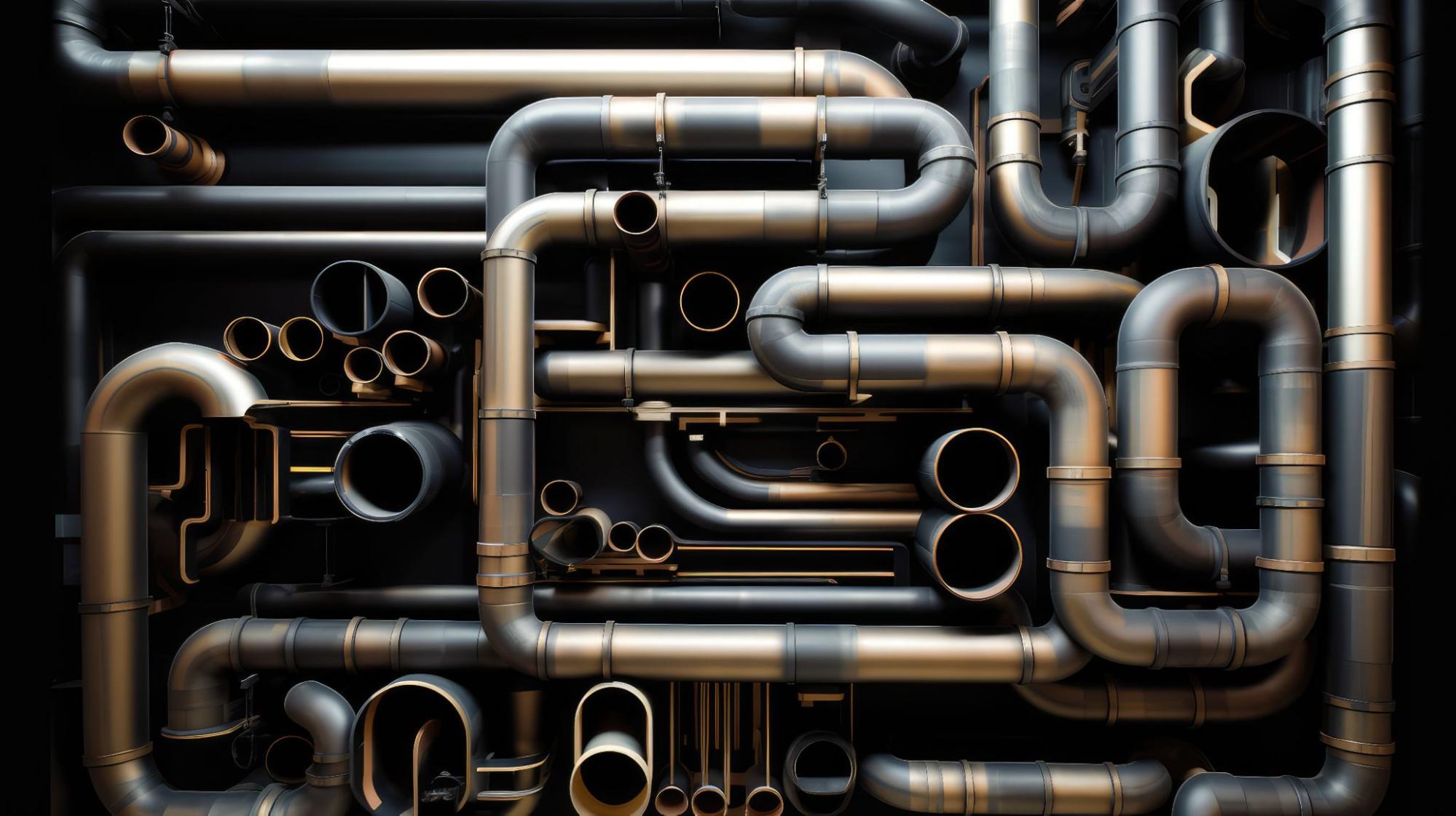

Tube Bending

Specializing in tight radius and thin wall bending, we bend aluminum, stainless steel, titanium, mild steel, d.o.m. and Inconel for aerospace, automotive racing, medical, and commercial fields. All bending is done with mandrels. (.250″ – 4.0″) Square and round.

EDM

We use Electrical Discharge Machining for harder metals or metals that would be more difficult to machine using conventional techniques. Typically used with electrically conductive materials, Wire EDM offers a wide range of possibilities.

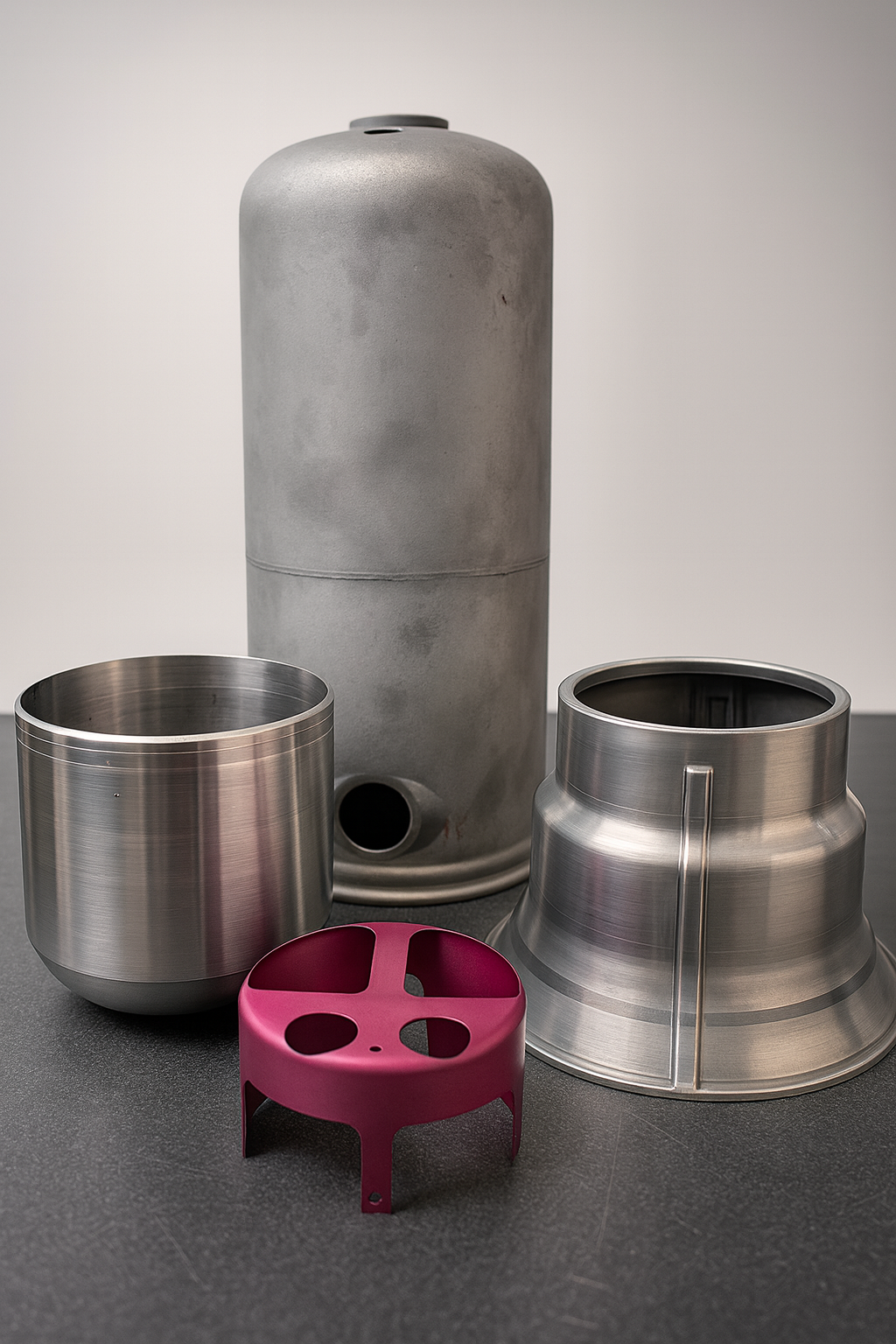

Metal Spinning

Also known as Spinning or Spin Forming. This is a metal manipulating method by which a disc or tube of metal is rotated at various speeds and formed into an axially symmetrical part. We perform spinning by hand and on CNC Lathe.

Precision metal spinning for aluminum and stainless parts titanium, inconel, tantalum—ideal for lighting, aerospace, and custom enclosures and military parts.

Commercial applications include nose cones, cookware, cylinders, brass instruments, bells, and waste receptacles. Virtually any pliable metal may be formed from aluminum or stainless steel to high-strength, high-temperature alloys.

Deep Draw Press

Our deep draw press is used in metal working to shape flat sheet metal into hollow, cup-like or box-like shapes by pulling (or “drawing”) the material into a die cavity.

Assembly and Custom Orders

We assemble all types of orders, quantities, and difficulties. Your requirements and specifications are our top priority.

Why Research Metal

Research Metal Industries is committed to providing products and services that meet or exceed customer requirements and applicable statutory and regulatory obligations. We maintain compliance with all relevant standards and pursue continual improvement of our Quality Management System through employee training, investment in advanced equipment, and the systematic elimination of non-value-added activities. This policy provides the framework for establishing and reviewing quality objectives at all levels of the organization.

At Research Metal Industries, quality is at the core of everything we do. We take pride in delivering precision, reliability, and value that our customers can depend on. By continually training our team, upgrading our technologies, and improving our processes, we ensure every project meets the highest standards of craftsmanship and performance.